Commodity Manager

Pickle Robot

Charlestown, Boston, MA, USA

Posted on Feb 8, 2025

Pickle is on the hunt for a dynamic and driven Commodity Manager to help shape the future of warehouse automation. In this role, you'll take the lead on sourcing, procurement, and supplier management for the critical components that power our cutting-edge robotics. You'll develop and execute strategic sourcing plans, build strong supplier partnerships, and ensure we have the right parts at the right time—all while driving cost savings and mitigating supply chain risks. This is a high-impact role where you'll collaborate cross-functionally to support engineering, operations, and product teams in bringing our robots to life.

What You’ll Accomplish:

- Commodity Strategy Development: Develop comprehensive commodity strategies aligned with organizational objectives, market trends, and supplier capabilities.

- Supplier Management: Identify, qualify, and manage relationships with strategic suppliers. Conduct supplier evaluations, negotiations, and performance reviews to ensure alignment with quality, cost, and delivery requirements.

- Procurement: Lead the procurement process for electronic and mechanical robotics components. Collaborate with Engineering and Product teams to identify sourcing requirements and technical specifications. Lead the sourcing process for assigned commodities, including RFQs, bid evaluations, supplier selection, and contract negotiations. Drive cost reduction initiatives while maintaining quality standards and supplier relationships.

- Market Analysis: Monitor market dynamics, industry trends, and regulatory changes affecting assigned commodities. Utilize market intelligence to anticipate risks, opportunities, and potential supply chain disruptions.

- Risk Management: Proactively identify and mitigate supply chain risks, including supplier capacity constraints, geopolitical instability, and raw material shortages. Develop contingency plans to ensure continuity of supply.

- Cost Management: Analyze cost structures, pricing trends, and total cost of ownership for assigned commodities. Implement cost reduction strategies, value engineering initiatives, and competitive benchmarking to optimize procurement costs.

- Cross-functional Collaboration: Collaborate closely with internal stakeholders, including Engineering, Operations, Quality, and Finance teams, to align commodity strategies with business requirements and priorities.

- Contract Management: Draft, review, and negotiate supplier agreements, contracts, and terms of engagement. Ensure compliance with legal, regulatory, and ethical standards. Continuous Improvement: Drive continuous improvement initiatives across the supply chain, including process optimization, technology adoption, and best practice sharing. Leverage data analytics and performance metrics to measure progress and drive efficiencies.

- Support rapid prototyping requirements by developing key partnerships and agreements to provide this capability.

- Support the Supply Chain team with other tasks. We're a small team that supports each other in all Supply Chain areas from Inventory Management to Logistics.

Who You Are:

- Bachelor's degree in Electrical or Mechanical Engineering, Supply Chain Management, Business Administration, or related field. Advanced degree or professional certifications (e.g., CSCP, CPSM) preferred.

- 5-7 years of experience in supply chain, commodity, and supplier management in a fast paced global sourcing and operations manufacturing environment.

- Solid understanding of manufacturing processes around electromechanical components.

- Demonstrated ability to work in a fast-paced, ambiguous environment while prioritizing and managing multiple stakeholders, responsibilities, and delivering multiple programs with aggressive schedules.

- Proven track record of managing supplier relationships, negotiating contracts, and driving cost savings initiatives.

- Excellent analytical skills with the ability to interpret technical data, conduct market research, and make data-driven decisions.

- Excellent negotiation, communication, and interpersonal skills.

- Knowledge of global regulatory requirements, industry standards, and best practices in electronics procurement and contract manufacturing.

- Experience with ERP and PLM Systems.

- Willing and able to work from our Charlestown, MA warehouse and headquarters in Cambridge, MA at least 3 times per week.

About Pickle Robot

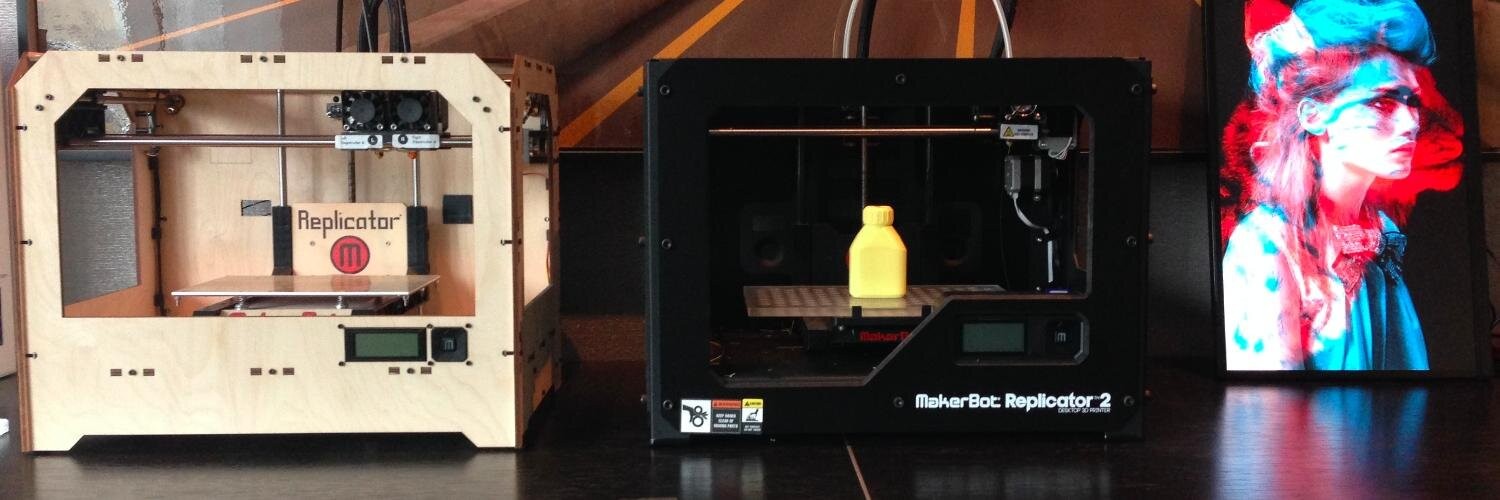

Pickle Robot is a pioneer in Physical AI for supply chain applications. Today Pickle robots autonomously unload trucks, trailers, and import containers at human-scale or better performance. The alternative is manual work that is difficult, dirty, sometimes dangerous, and increasingly hard to staff at distribution centers around the globe. Pickle Robot is laser focused on automating truck unloading using generative AI, machine learning, computer vision, advanced sensors, and industrial robotics to deliver engineered products customers rely on. Pickle Robot Unload Systems work alongside people on loading docks to make the work safer, faster, and more efficient. Pickle robots are physical AI that unload trucks.

Pickle provides best-in-class benefits including health, dental, & vision insurance; unlimited vacation, along with all federal and state holidays; 401K contributions of 5% your salary, travel supplies, and other items to make your working life more fun, comfortable, and productive.